Studying automotive engineering in Finland

So I have currently studied one semester of automotive engineering in Finland. The first year is heavily focused on getting basic understanding of physics, maths and other engineering related subjects, as not as much of automotive engineering subjects. Only actually fully automotive subject we had last fall was the beginning of our entry project.

In this project we were set out to build a electric go-kart from the chassis up. We only got few pieces like the electric motor, battery and controller ready and were not to modify them. Our group consists of currently 8 students, and last wednesday was our first day we got to start the actual build of the "go-kart".

On the build day we had one goal. We had to get the chassis all cut to length and then welded up solid. It was a lot of work and since most of us never had build anything like this before there were some kinks and miss cuts made, but with some smart decisions those problems were overcome and made to work for us.

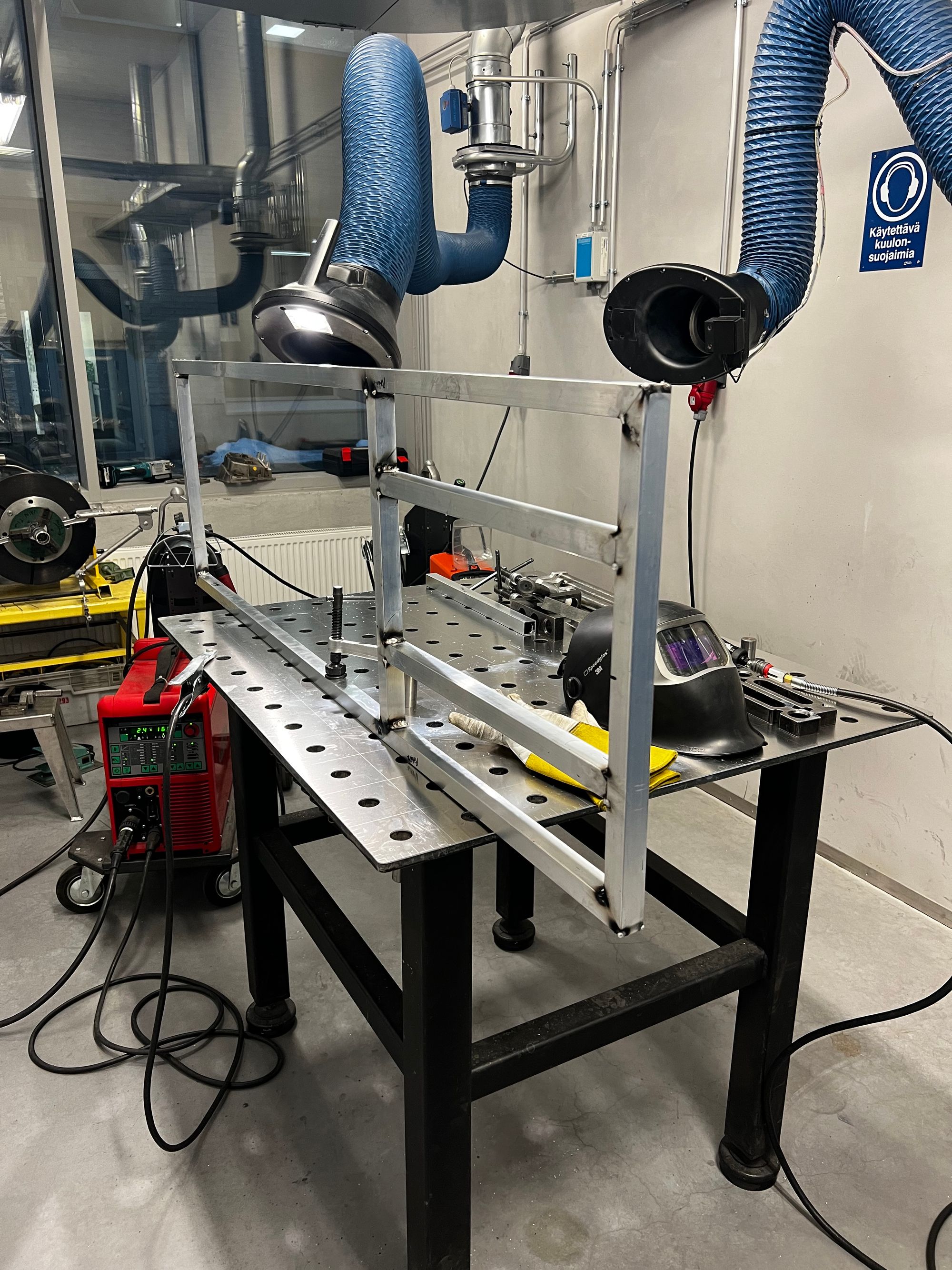

My task for that day was mainly be the welder. I set up both mig and tig welders for welding roughly 3mm thick aluminium. Frame was build from 30x30x3 tubular aluminium. This had weight benefits over steel but made welding it a little bit more difficult. I was hoping to get as much of the tacks done by tig as possible, but in the end with our timetable being so limited of 3 hours for fabrication. I switched fully to mig welding the whole chassis.

When you are welding a large object like our kart´s chassis which will have lot of seams to weld and thus lot of heat introduced to it. It´s a good idea to think about in which order would you weld all the seams up. I started by tacking up the outer frame first, then changed to welding the rears reinforcements in on the lateral seams. I ended up welding all lateral seams up first which made the chassis resist torsion quite well and also kept moving the welding points across the chassis never giving too much heat to one spot at the time. I eventually welded a bit over 3 hours, but we met our goal and got the frame fully welded up. Now in the next weeks it more machining side of things to get all the parts ready for the final build of the go-kart.

I´ll do a whole series of post on our go-kart build. From the design aspects to our build of electric mini formula.

This spring I´ll be studying more mathematics, physics, statics, programming and excel. From these I´ll try to make educational posts if you are interested to know how these are taught in finnish polytechnical.